Services

Scope of Services:

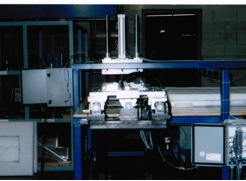

- Automated/Semi-Automated System Design and Build

- Material Handling System Design/Build

- Manufacturing Consulting

- Injection Mold Design/Build

- Custom Injection Molding

- Assembly Cell Creation

- Material Process Consulting

- Special Material Cleaning Equipment for Reprocessing Electronics

- Cryogenics [liquid production/gas application/heat exchange]

- Safety Compliance Evaluation/Correction (compliance categories applied – OSHA / FM / UL / FCC / ETL / CE)

Customer Advantages:

- Fast turn-around on all design and build processes

- On-site Consultation for Product/Process Evaluation

- Competitive Pricing

- Rapid Response for Mission Critical Requirements

- Full Design/Engineering Services

- Guided Compliance Testing for product approval (ETL, UL, FCC, IBC, CE, FM, Etc)

- Independent lab testing for product safety and engineering stability

- Product Failure Testing / Reporting

Engineering and design services include mechanical, electronic (hardware/software/firmware), hydraulic, and pneumatic.

In an effort to help our clients and prospective clients understand the possibilities before them by way of goods and services possible to facilitate their needs, this description is being presented as a basic guide for future project considerations.

Design/Engineering Services:

- Consumer electronics (all types for all applications)

- Software

- Firmware

- PCB/PWA layout and execution

- Wiring harness design

- Mechanical design engineering

- Robotics

- Automated systems

- Air logic

- Tooling (Injection Molds, Blow Molds, Roto-Cast Molds, Vacuum Form/Thermo Form molds, Progressive stamping dies, precision inspection fixtures, etc.)

Prototyping:

- SLA

- Machined

- Plastics (all types)

- Metals (all types)

- Forming

- Vacuum molding

- Proto injection molding

- Fabrication/welding

Production:

- Production machining

- Molding

- Forming

- Assembly

- Packaging